Comansa Cranes Eugene

Linden Comansa was a corporation which began manufacturing tool and jig during the early 1960s. They went by the name "Imausa". The company began supplying mostly the bigger sub-contractors to the then booming automotive industry

There was a strong industrial expansion in Spain during that same time. This period saw Imausa making more advanced machine tools, jigs and different types of tools for both external and in-house applications. The corporation even specialized in manufacturing pre-fabricated steel structures specially for industrial buildings.

Imausa's initiation into the crane market was an almost inevitable if not logical step. The Spanish tourist industry exploded to rapidly become amongst the world's biggest tourism magnets. This mass expansion of course brought a parallel demand for housing, hospitals and schools amongst different other things. The company became extremely busy, very fast.

Production

The first simple cranes produced were saddle-jib. These equipments were best suitable for the specific building methods being utilized during that time. The very first crane model eventually grew into a range of cranes with a capacity ranging from 12 to 42 metric-tons.

By the early 1970s, Linden Comansa saddle-jib cranes had already met the 200 metric-ton barrier. Linden Comansa has surpassed the standard and has continued to design and engineer cranes that exceed the 900 metric ton capacity. There is currently manufacturing and design facilities which permit the development and production of more spectacular and even larger equipments.

There are several specific advantages offered by the unique Linden 8000 Modular System crane, which made it a logical addition to the range Linden Comansa offered to customers all around the globe. These global customers have bought roughly 12,000 Linden Comansa cranes in addition to the roughly 6000 machines made in Sweden by Linden-Alimak. These various other cranes were manufactured prior to the acquisition of the world-wide manufacturing and selling rights of this particular modular system.

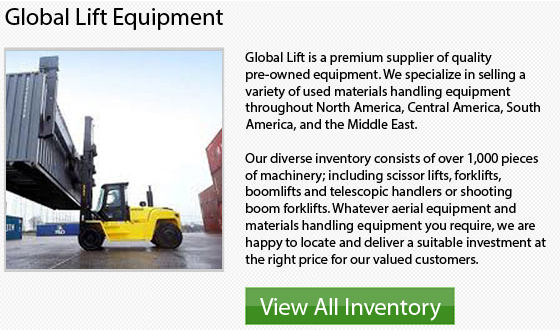

- Manitou Gas Forklift Eugene

The majority of companies would turn to the forklift to help them transport specific things from place to place or to complete specific jobs. Prior to buying a forklift, this is why it is essential... More - Jungheinrich Propane Forklift Eugene

Lift Truck Parts in More Detail There are hundreds of parts that make up a lift truck. The forklifts major components include the frame of the truck, the engine components, the tilt cylinders, the overhead... More - Toyota Counterbalance Forklift Eugene

Toyota has been among the top dealers of innovative lift trucks for over 40 years. The company has sold over 1 million forklifts up to this date. Toyota has earned a solid reputation and has... More - Snorkel Scissor Lifts Eugene

Platforms which use a scissor-like mechanism to be able to lower and raise the apparatus are referred to as scissor lifts. Normally, this specific type of material handling machine only moves vertically. The mechanism which... More - Snorkel Knuckle Boom Lift Eugene

A knuckle boom crane looks like a typical crane. The main difference is that the boom is capable of folding back similar to a finger as the boom articulates at the "knuckle" near the middle.... More