Daewoo Lift Truck Eugene

Forklift Safety and Forklift Training:

Forklift safety training is the employer's responsibility. It is in the employer's best interests to spend money on forklift training for all employees. Improperly utilized forklifts can cause property damage. Businesses could be sued if there are injuries. It's truly worthwhile to make sure that anyone using a forklift is correctly trained to do so.

In order to make certain that forklift operation is safe, a forklift training course must be attended by each and every worker.

All the workers must be aware of forklift basics. Information regarding safety should be provided in the form of handouts, and posted in warning signs and posters. The following are several important forklift training and safety tips:

1) An employee can only use a forklift if he or she is licensed. Never take risks with such big machines. Forklift training must be taken very seriously.

2) Seat belts should always be utilized by forklift operators. Just because the forklift moves slowly doesn't mean that seat belts can be disregarded. Accidents are less likely to result in personal injuries when seat belts are worn.

3) Establish a system for workers to report instances of damage or mechanical problems. As the employer, you need to create an efficient and effective reporting system that is easy to figure out. Employees must be correctly trained in forklift basics so that they could detect and report issues when they occur.

4) Training workers to lean away from the turn, and stay in the cab even when there is a possibility of overturning is really important. Employees must not jump out. That's the best way to avoid serious injury.

5) Staff need to be trained to know a forklift's weight capacity limit. A major cause of forklift accidents is related to tip overs caused by lifting extremely heavy loads. Workers must really know how much they can safely lift. A tip over can damage the whole forklift. Overloading is the biggest safety mistake an employee can make.

- Manitou Gas Forklift Eugene

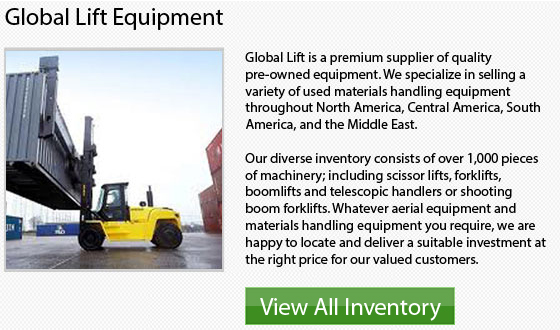

The majority of companies would turn to the forklift to help them transport specific things from place to place or to complete specific jobs. Prior to buying a forklift, this is why it is essential... More - Jungheinrich Propane Forklift Eugene

Lift Truck Parts in More Detail There are hundreds of parts that make up a lift truck. The forklifts major components include the frame of the truck, the engine components, the tilt cylinders, the overhead... More - Toyota Counterbalance Forklift Eugene

Toyota has been among the top dealers of innovative lift trucks for over 40 years. The company has sold over 1 million forklifts up to this date. Toyota has earned a solid reputation and has... More - Snorkel Scissor Lifts Eugene

Platforms which use a scissor-like mechanism to be able to lower and raise the apparatus are referred to as scissor lifts. Normally, this specific type of material handling machine only moves vertically. The mechanism which... More - Snorkel Knuckle Boom Lift Eugene

A knuckle boom crane looks like a typical crane. The main difference is that the boom is capable of folding back similar to a finger as the boom articulates at the "knuckle" near the middle.... More