Jungheinrich Dual Fuel Forklift Eugene

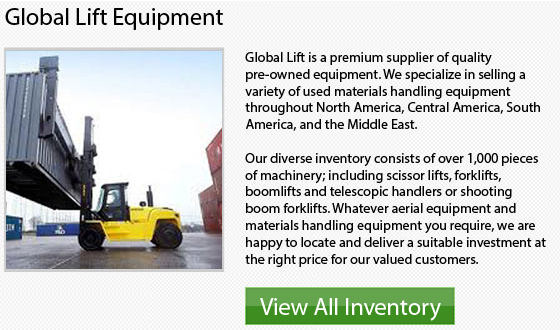

Important equipment used on construction sites comprise vehicles such as the lift truck, the bulldozer and the bobcat. Lift trucks could range from extremely huge to fairly small units. These types of machinery are made to pick up loads and transport products and materials in retail or warehouse environments. Many are made to easily maneuver in narrow, confined areas. It takes both training and skill to properly use a forklift.

The forklift can be found in almost every factory, warehouse, and distribution center because they have become vital pieces of machines used for handling materials. Inside warehouses and stockrooms, the forklift is utilized to lift and move goods and supplies to store them up high. They are essential for productivity in work environments where there is a large variety of stock and a small place to keep it in. These trucks are made to move huge pallets around in factories.

Anyone using a lift truck should be trained how to drive and operate this piece of machinery. Training could be done on the job or in a formal training setting. usually training is delivered at the workplace. Training and accreditation often means a raise for the person obtaining new skills. Lift trucks have standard operating measures, that makes it easy to get trained on different types of lift trucks.

Smaller equipment accommodate a single operator in the cab and can maneuver in small, tight areas. The larger machinery are massive and can carry trucks, cars or other heavy pieces of machinery. Forklifts can lift thousands of pounds easily.

Normally, construction companies will give salary raises to workers who go through training. Employers will normally send an employee to classes to train on a big piece of machinery. Willingness to train on a bull dozer, a forklift or a bobcat will certainly pay off.

- Manitou Gas Forklift Eugene

The majority of companies would turn to the forklift to help them transport specific things from place to place or to complete specific jobs. Prior to buying a forklift, this is why it is essential... More - Jungheinrich Propane Forklift Eugene

Lift Truck Parts in More Detail There are hundreds of parts that make up a lift truck. The forklifts major components include the frame of the truck, the engine components, the tilt cylinders, the overhead... More - Toyota Counterbalance Forklift Eugene

Toyota has been among the top dealers of innovative lift trucks for over 40 years. The company has sold over 1 million forklifts up to this date. Toyota has earned a solid reputation and has... More - Snorkel Scissor Lifts Eugene

Platforms which use a scissor-like mechanism to be able to lower and raise the apparatus are referred to as scissor lifts. Normally, this specific type of material handling machine only moves vertically. The mechanism which... More - Case Rough Terrain Forklift Eugene

Case equipment are amongst the fastest machines within the business and offer zero tail swing and an ease of operation. These lift trucks are built to deal with the most difficult rough terrain environments head-on.... More