Caterpillar Lift Trucks Eugene

How to lessen the cost of damage to fork lift trucks

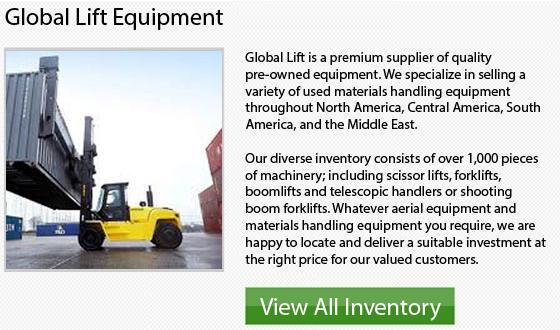

There are some common reasons for forklift truck damage, no matter what the workplace may be. Instances of damage can be extremely costly. Expenses commonly relate to costs of staff downtime and repair. Luckily, most kinds of forklift truck damage can be avoided. By following these simple steps, fleet operators could ensure that repair costs and downtime are avoided or minimized.

Check that the machine is appropriate for the task and the surroundings. Perform safety checks on vital systems and truck parts. Be certain that forklift drivers are well trained and that supervision is provided. Examine the layout of the operating area/warehouse to ensure it facilitates movement. Develop a repair/maintenance plan that could guide actions when anything goes wrong.

Even though the working environment is mostly the cause of accidents, fault can be sometimes be the actions of the drivers. A safe working surrounding involves having the correct machine for the application.

Taking a long-term and coordinated view of fleet management is the most cost-effective approach. The instances of damage can be reduced a lot by having the same company that supplied the trucks train the drivers and carry out maintenance and repairs. The company could also offer suggestion about the design of the warehouse.

- Manitou Pneumatic Tire Forklift Eugene

A pneumatic or air-filled tire is composed on an inner core which is filled with pressurized air and sealed airtight. Usually, a reinforced steel belted tread or other materials, provides the contact part with the... More - Jungheinrich Propane Forklift Eugene

Lift Truck Parts in More Detail There are hundreds of parts that make up a lift truck. The forklifts major components include the frame of the truck, the engine components, the tilt cylinders, the overhead... More - Toyota Counterbalance Forklift Eugene

Toyota has been among the top dealers of innovative lift trucks for over 40 years. The company has sold over 1 million forklifts up to this date. Toyota has earned a solid reputation and has... More - Snorkel Scissor Lifts Eugene

Platforms which use a scissor-like mechanism to be able to lower and raise the apparatus are referred to as scissor lifts. Normally, this specific type of material handling machine only moves vertically. The mechanism which... More - Case Rough Terrain Forklift Eugene

Case equipment are amongst the fastest machines within the business and offer zero tail swing and an ease of operation. These lift trucks are built to deal with the most difficult rough terrain environments head-on.... More